Lithium Processing Plant Uses ScatPumps to Reduce Pump Maintenance

Stewart Bailey is the Area Manager – Process Infrastructure for Altura. The company is on track for the commissioning of its lithium processing plant in the Pilbara. In this interview, Stewart discusses deploying the ScatPump submersible slurry pumps to replace existing pumps that were struggling to handle the operating conditions.

Can you describe your operation?

Can you describe your operation?

We’re a junior mining company with a brand-new process plant that we are commissioning and ramping up to nameplate completion.

What were the problems that you were having with your old pumps?

The original equipment selection was based on trying to standardise our pumps across the site. The pumps we’d chosen are generally regarded as the industry’s best, but there are very few spodumene process plants currently in operation to take the experience from, and under our particular conditions, the originally chosen pumps were not performing as expected.

Because they weren’t performing both in terms of efficiency and wear life, they became an ongoing maintenance and operational burden on the team. Thus, the project team, which I head up, was tasked with finding an alternative pump type that would perform better and reduce the amount of labour required to keep the pumps operational.

Why did you decide to try PumpEng?

PumpEng were recommended by another supplier as being the most suitable for our application. This led me to make an enquiry.

PumpEng gave me a brief run-through of their products over the phone and quickly followed up by issuing all of their pump data and stock availability. They had pumps available immediately off the shelf, and this was one of the deciding factors in going with PumpEng initially as a short-term solution.

Official quotes were quickly received, showing competitive pricing, much lower than the current pumps that we were using. An order was placed for a trial pump, and within days, the pump arrived on site.

How many pumps do you have there now?

Our initial order was for one trial pump which was used to replace our hardest-working and most problematic sump pump. That pump was received very well by the guys on site because of the ease of installation. This was especially because it was compatible with all of our existing control set-up. Then as soon as it was put into use, it started performing well, and the Projects Team quickly received requests to commence with ordering further pumps for some of the other problem areas. It was decided that these pumps were more than a short-term solution, and because of their suitability and value, they should be used sitewide. Another three were immediately ordered, taking us to four, with three in use and one spare. We ordered a spare as part of the PumpEng exchange program, which was also part of the deciding factors.

Since then, we’ve received a request for a further three, which are now on site, with further requests coming in each time one of the original pumps has a problem.

Which of the pumps do you have there?

We try to standardise them by having all 9kW Scatpumps. There was a bit of lead time with a later order of 9kW pumps due to stock availability, so we went ahead and purchased two 7.5kW and one 15kW from the ScatPump range. This wasn’t a problem for us as the different-sized pumps are interchangeable in our setup, and it allowed us to trial the smaller pumps to reduce our power consumption.

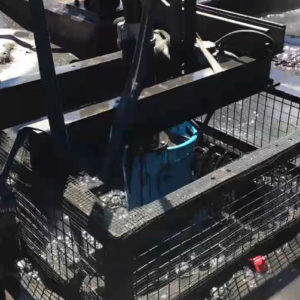

Can you describe where you are using them?

In our sumps under the fixed plant. There’s slurry, wash down and also ferro silicate product from our dense media separation units. Recovering the water from the sumps is essential for our water balance. Therefore, it’s essential that the sump pumps perform well so no water is wasted. Making the sump pumps an essential part of the process.

How do you describe their performance?

They are performing excellently in carrying out their duty and doing exactly as we require them to do. The previous pumps had a two-stage operation where in the first stage, they agitated the material in the liquid, and in the second stage, they pumped. The ScatPump doesn’t need agitation prior to pumping. They just agitate as they pump, resulting in continuous pumping. This means that the pumps are able to keep up with high demand and maintain lower levels of liquid in the sumps, which means the faster recovery of the water into that water circuit.

There is also a safety factor to add in there. The ScatPump maintains a lower level in the sump which means the operators aren’t working around higher water levels.

Is it too early to tell how much more performance you’re getting out of these than the others?

It is early days, but we haven’t had an issue with any one of them. Two have been on site for four months, so that is a big improvement. Previously the old pumps were a constant, almost daily, maintenance issue for us.

To date, I have not received any negative reports. The only feedback that I’ve received is the requests that come in to purchase more of them.

How would you describe PumpEng’s customer service?

The PumpEng people we deal with have been excellent. They’ve been very responsive with everything we’ve needed. They are quick with quotes and making the pumps available.

What would you say to someone who’s thinking about switching to PumpEng for their dewatering pumps?

I’d say there’s no reason not to use them because they’re available in WA, serviced in WA and their performance, reliability and price is right. They don’t come with a big brand name reputation that you end up paying for. In this case, you get the pump you want at the cost you want, and it performs.

The PumpEng pumps save us time in pump maintenance. They save plant operator time in cleaning up around the areas because the pump is maintaining a lower level of liquid in the sumps. They increase the water recovery which we need from the sumps.

We are a brand new process plant so there are lots of issues we need to tackle. Having these success stories allows our time to be spent focussing on other issues. You want to find a solution and implement it, you don’t want your solution to end up being one of the problems. So, finding PumpEng ScatPumps was a success which took one of our problems away.

View Pump Specifications: ScatPump Submersible Slurry Dewatering Pump

Product Range:

Guardian® | JetGuard® | Raptor® | ScatPump® | MetalVest™

By Application:

Mining Pumps |

BIBO Compatible Pumps | Dirty Water Pumps | Slurry Pumps | High Head Pumps

Quick Links:

Pumps | Pump Shop | Pump Parts | Pump Service | Pump Hire | Contact