Mining Pump Range

PumpEng is an independent Australian company that designs, manufactures and services mining pumps for underground dewatering operations worldwide.

Dewatering Mining Pumps available for sale - contact us today for more information or advice.

JetGuard®

Shotcrete Capable Dewatering Pump

The JetGuard® submersible dewatering pump is designed for underground and surface mining dewatering, as well as general purpose dewatering.

JetGuard® has specific design features to handle Shotcrete reinforcing fibre, helping to reduce repair costs for pumps and pump stations while improving reliability.

Raptor®

Dewatering Pump

Submersible dewatering pump suitable for underground mining, surface mining and other general dewatering requirements.

Parts fully interchangeable with traditional OEM BIBO range of pumps.

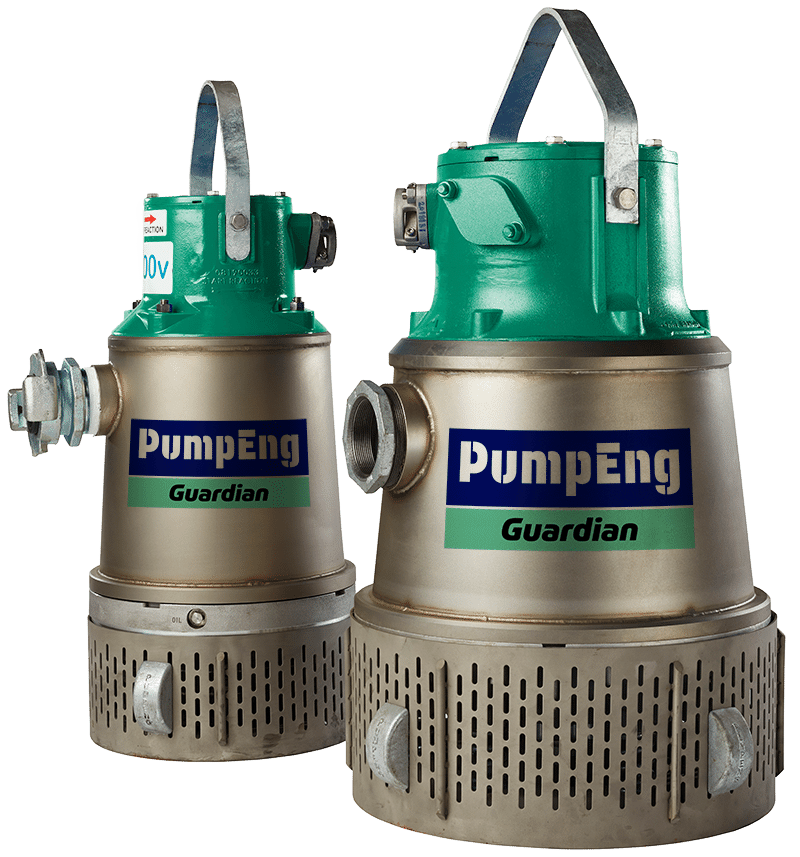

Guardian®

Dewatering Pump

Tougher pump for harsh underground environments.

When pumping tramp and solids is unavoidable use hard metal.

Designed for longer life.

ScatPump®

Slurry Pump

The ScatPump® range of slurry submersible pumps are designed to handle solids, and can be a more user friendly alternative to vertical cantilever pumps.

The ScatPump® range is designed to offer set and forget submersible slurry pumps. Uses high chrome impeller, agitator and wear plates.

MetalVest™

High Head Pump

MetalVest™ submersible pumps use a full metal build, so there is no urethane or rubber lined parts for a longer life.

The cylindrical MetalVest™ Slimline is designed for those places where physical size is an issue. It fits inside caissons for offshore requirements.

12 Selection Criteria For Choosing Submersible Pumps in Mining & Construction

Quick Menu

Underground mining pumps need to be fit for their purpose.

To help you get the right mining pump for your specific purpose, we've outlined 12 criteria to help you in your selection and evaluation. These criteria will include factors relating to your mining or construction site, but there are also critical administrative issues that will ultimately affect how the pumps will perform.

Sometimes what seems to be common sense isn't the best approach - for example, bigger is not always better. If you install pumps with more capacity than required - just in case - you may end up with more frequent pump failure from overheating.

So here are the twelve selection criteria that need to be considered in choosing a mining pump.

- Pump Capacity - How big a pump is actually needed?

- Quality of Liquid - What type of liquid is to be pumped from inside the site?

- Safety - Could the choice of this pump have an impact on site safety?

- Gradient/Height - How steep is the ground that needs to be pumped over?

- Pipe Length - How long is the pipe carrying the water out of the mine?

- Pipe Diameter - What is the outside measurement of the pipe?

- Pipe Class - What is the inside measurement of the pipe?

- Site Trial - Will the supplier provide a test pump to measure performance at your site?

- Service Backup - How quickly can a pump be replaced?

- Cost of Servicing - Does the service contract have hidden costs?

- Consulting - Does this supplier offer onsite problem-solving?

- Energy Rating - Is the energy rating of this product based on field or factory conditions?

Pump Capacity - How big a pump is actually needed?

To choose the right pump you need to accurately estimate the capacity that is required. Sometimes an error is made in estimating how much water needs to be pumped. Someone might assume they want to pump 10 litres per second but in fact, they've only got 2 litres per second. In those circumstances, the pump is going to overheat and burn out.

Quality of Liquid - What type of liquid is to be pumped?

What is in the wastewater to be pumped? It is important to know how caustic the liquid is. The most corrosive/abrasive materials are the ones that affect which pump the most. An example of this is cyanide, which you will find in some wastewater. Pumps with all metal parts are more resilient in these type of environments.

Safety - Will the choice of this pump have an impact on mine or construction site safety?

Safety is never left to chance on professional worksites. Most aspects of the operation are thought through carefully. From the boots up, clothing is designed to protect. Vehicles and equipment are task-specific. Training and procedures are set out for every job. It is all about avoiding risk.

Dewatering Often Unplanned

It is a surprise then, to go underground and see how random the dewatering process often is. If you compared pumps to vehicles, you'll see the equivalent of a mini minor towing a trailer and then around the corner you'll see a Mac truck towing a trailer. The mismatch leads directly to increased risk for maintenance crews as well as costly replacement and maintenance. The increased risk is created when cheaper pumps cause more breakdowns. Maintenance events increase handling and exposure to high-risk environments for the maintenance crews who have to replace failing pumps.

Gradient/Height - How steep is the ground you will be pumping over?

What sort of gradient will you need to pump liquid over? What is the height of the surface that you will be pumping water to?

Pipe Length - How long is the pipe carrying the water out of the site?

Length is an important issue due to the friction created as the liquid flows through a pipe. For every 100 metres, you will see a reduction in flow. As soon as you start getting steeper and steeper, you will see that loss of flow from distance plus that loss of flow from the pressure of pumping uphill.

Pipe Diameter - Why is the outside measurement of the pipe?

A customer ordering a pump might say they've got a 200 ml pipe. If it is a Poly Pipe the pipe diameter is actually measured on the outside diameter, not the inside. A small error like this can have a major impact because it can cause pump failure or inefficient operation.

Pipe Class - What is the inside measurement of the pipe?

Pipe class refers to the inside diameter of the pipe. This is critical because you will be pumping the fluid through the internal space of the pipe.

The rating, which is what we call PR rating or the STR rating, is the inside diameter. So the smaller the rating, the less you can physically put through it.

The higher the rating, the thicker the wall, the more pressure a pipe will cope with. You can put a lot more pressure through it, but obviously less flow.

If you're talking about a pipe that's PN10, which is 10 bar, it's rated to hold 10 bar of pressure. Now, with any manufacturer, they always rate it lower. So in theory, they'll be able to hold 30 bar.

An issue arises on mine sites with wear on the pipes. For example, you might see a mine site where the Poly Pipe is hooked to the back of a Land Cruiser. The pipes will be dragged along the ground when it's moved. The wear caused by the dragging means that the pipe walls get thinner. They might become very brittle.

It might be rated 10 bar and you put 9 bar through which should be fine. However, if the pipe is not maintained and looked after, it can explode. Having Poly Pipe explode with 9 bar of pressure is enormously loud. It won't just be a little hole, it can produce a split of up to 15- 20 metres long.

Site Trial - Can you test mining pump performance at your site?

There is an increasing trend to test equipment in the field. Most mining pumps come with performance ratings based on laboratory conditions. Gradually we are noticing a shift to equipment procurement based on tested field performance.

The reason for this shift is that the performance of a pump over its lifetime is a lot more important than its Day One performance.

A mining pump that gives an impressive performance on Day One can seem like a great choice. However, if the performance of that pump dramatically reduces over time, you rightly start to question your investment. You start to see that the pump can't cope with the conditions or the application.

Pumps perform differently in the factory than they do in the field. Printed performance curves that are only based on ideal conditions are not going to accurately predict performance in tough field conditions.

Engineers can replicate the testing standard back at their workshop. They set up the pumps, polish the internal surfaces to a mirror shine to reduce internal friction, and add back velocity head and testing tolerance to meet the curve. It's legal, but it's not right.

That is why it is important to test pumps to see exactly how they perform in a more challenging environment like your own work site.

Service Back-Up - How quickly can a pump be replaced?

If a pump needs repair, how quickly can you get a replacement? Once it is repaired - how does the pump perform back on site? Ideally, you should be looking for suppliers who can show evidence of a quick turnaround in replacing pumps. You also need to see a track record of quality maintenance. Do the pumps that return to site deliver the high standard of performance that you need? You need both speed and quality.

Cost of Servicing - Does the service contract have hidden costs?

A service contract that is too cheap may have hidden costs. You’ll see examples of this when a pump breaks down just after a service. Why? This can be the result of a partial service, rather than a full service. A business aiming to deliver a cheap service contract can charge less maintenance costs because less work is done. Only half the parts that need regular replacement may be replaced. A pump breakdown immediately after a service is a clue that you might be getting a part service rather than a full service.

Does mining management see the connection between the initial price paid and the resulting performance? Not always.

That is why we suggest that when looking at the capital costs associated with submersible pumps, always factor in the total cost of ownership (TCO). If you factor in cheaper pumps, you should also factor in a higher level of risk that production delays may occur. There will be more frequent replacements and repeat service calls. Managers know how to model operations, the same approach needs to be applied to dewatering infrastructure.

So broadly speaking, there are two TCO approaches for purchasing submersible pumps - you can target low upfront cost, higher ongoing costs and more downtime, or target higher upfront costs, lower ongoing costs and lower downtime. Each site is different, so do your own costings, make realistic assumptions and see what your TCO model shows.

Consulting - does a pump supplier offer free onsite problem-solving?

There are suppliers who just sell pumping equipment. There are other suppliers who back up that equipment with consulting from experienced industry professionals. Access to this higher level of expertise means that you can solve problems quickly. This can have an impact on whether production targets are met. Experienced consulting will also ensure you get maximum value from the equipment you have onsite.

Energy Ratings - Is the energy rating of this mining pump based on field or factory conditions?

Pump manufacturers want to produce pumps that use less power. Power usage is an important measure of efficiency for pumps.

Big pump manufacturers go hard after this and produce pumps that look like they are ecologically clean, green and environmentally friendly because they use less power and attract fewer emission taxes.

To demonstrate this, manufacturers have to show that their pump is hydraulically efficient. They put their pump in a test tank to get it certified. Often the pumps are tested using clean water. A pump tested in these conditions will return a maximum possible efficiency level because every element is controlled.

Take that same pump out into the real world, and things change. Take it into a tough environment - like underground mining conditions - and the game changes radically.

Tough environments introduce so many new factors that don't get covered or controlled in the lab. Forget clean water, think dirty water with lots of tramp. Forget air-conditioned comfort; it could get very hot or very cold. Forget being able to reach the pump to fix things - put a pump out in the field and it stays there until it breaks.

So what happens to your high-efficiency pump once you out in tough conditions? Efficiency and performance can drop off very quickly. All of those theoretic lab gains no longer apply.

People understand these principles of energy efficiency when they choose a car. You can design a small car to deliver great fuel efficiency driving around the city. If you have to go off-road, you take a 4WD. People understand why different vehicles are suitable for different conditions. It isn't as clear when it comes to pumps, it can be harder to see how they are designed to cope with tough conditions.

It is important to measure the performance of pumps in tough work environments. This is because it is pump performance over time that matters rather than how it performs on the first day.

If you're planning to acquire some new dewatering pumps you should ask questions about how the pump will hold efficiency over time. Arrange for a free trial so you can test out energy efficiency on site.

Product Range:

Guardian® | JetGuard® | Raptor® | ScatPump® | MetalVest™

By Application:

Mining Pumps |

BIBO Compatible Pumps | Dirty Water Pumps | Slurry Pumps | High Head Pumps

Quick Links:

Pumps | Pump Shop | Pump Parts | Pump Service | Pump Hire | Contact