PumpEng is on a mission to redefine underground mine dewatering, prioritising excellence at every turn. Our commitment to innovation, reliability, availability, and personalised support throughout the product lifecycle ensures every mine operator a good day at work.

We are an Australian-based global Original Equipment Manufacturer (OEM) with a proud history of manufacturing and supplying tough submersible pumps to the underground and surface mining sector.

PumpEng is a trusted global mining partner. Our core competencies include submersible pump design, manufacture, assembly and application guidance. A commitment to eco-friendly solutions reflects environmental responsibility.

Our client-centric approach fosters enduring partnerships worldwide, providing exceptional service and support. PumpEng upholds the highest standards and meets international regulations.

PumpEng stands as a beacon of global OEM manufacturing, epitomising reliability, innovation, and customer-centricity for the mining sector. We’re available, supportive, innovative and consultative.

PumpEng is an independent Australian company that designs, manufactures and services underground mine dewatering pumps for companies worldwide.

Have A Good Day At Work

“My project engineer is extremely happy. He does all the figures. The superintendents, they’re the ones who convinced me to pursue this in the first place and suggested a PumpEng site-wide trial. They were extremely happy with the longevity of the sump pumps.”

The PumpEng

Way

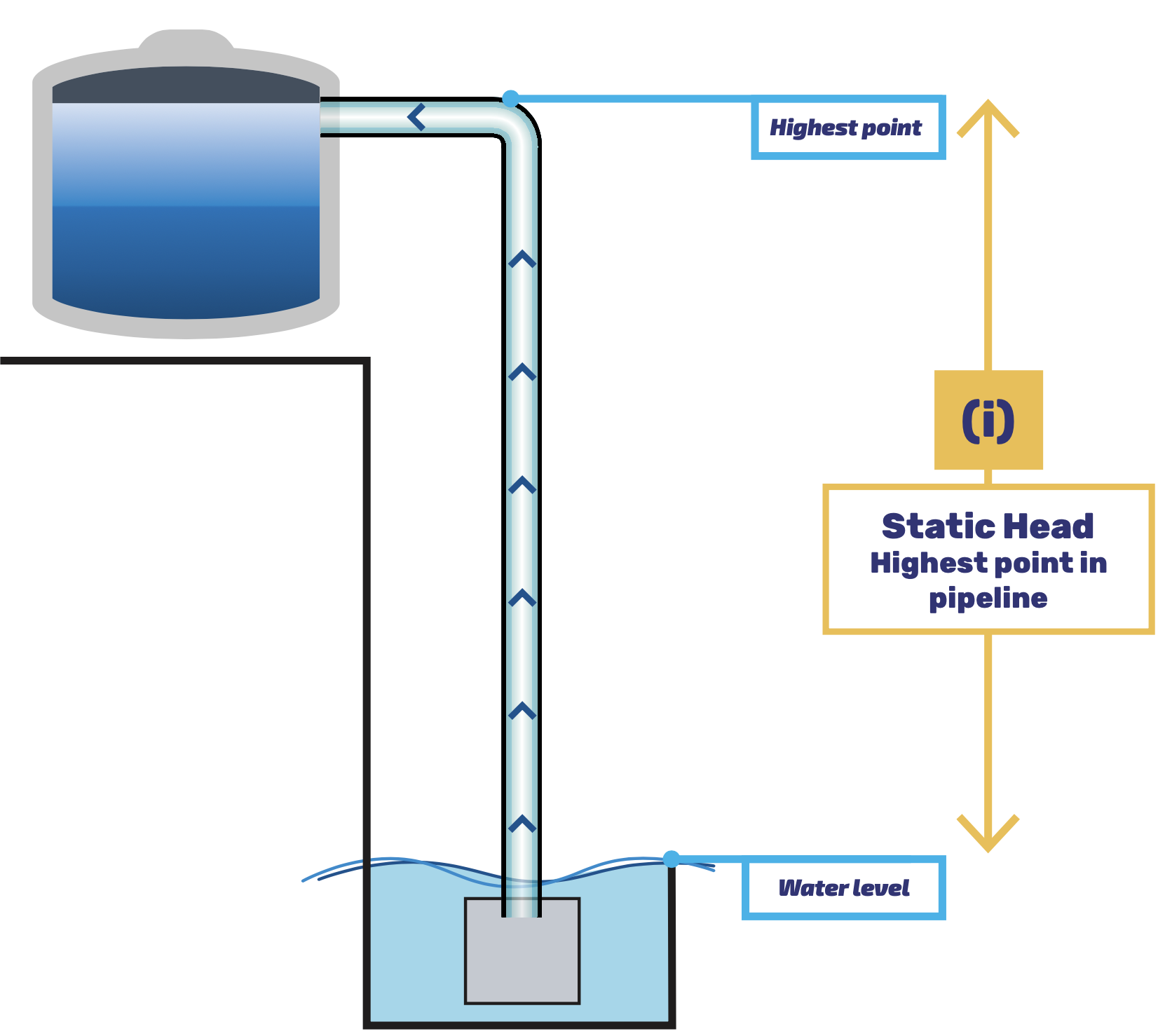

This is a process to ensure the right pump is used for the job to give you a good day at work.

Innovative

Australian Pumps

These are designed, manufactured here in Australia and supported by a worldwide supply and service network. These pumps will redefine your expectations of pump life.

Responsive

Customer Service

Efficient. Accurate. Timely. Friendly.

Professional. Reliable.

Try Out Hire To Solve Your

Worst Pump in Your Worst Sump

Pumps Available for Hire Now

Rates Start At $15 Day

No Minimum Quantity

Sensible Fair Wear & Tear Policy.

“We were hoping to be able to

put in a pump and not have to

worry too much. So that’s a

green tick

there…”

Maintenance Supervisor at Redpath’s Queensland operation

INNOVATIVE & COMPATIBLE

AUSTRALIAN DESIGN

MANUFACTURED IN

AUSTRALIA

BRANCHES IN

WA, SA, QLD,

NTH AMERICA, SE ASIA

INTERNATIONAL

DISTRIBUTION

Product Range:

Guardian® | JetGuard® | Raptor® | ScatPump® | MetalVest™

By Application:

Mining Pumps |

BIBO Compatible Pumps | Dirty Water Pumps | Slurry Pumps | High Head Pumps

Quick Links:

Pumps | Pump Parts | Pump Service | Pump Hire | Contact