Benefits of ScatPump® For Processing Plants & Difficult Sumps

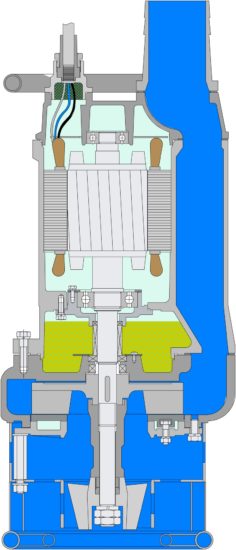

The ScatPump® is an extremely durable, top-discharge slurry submersible pump with a mechanical agitator and wide clearances. This slurry pump has a straight path from intake to discharge and uses the pumped liquid to cool the motor.

This slurry pump also does not have an elbow joint like a side-discharge pump, so it has fewer surfaces that can wear or potentially fail, and can fit into tighter areas. The ScatPump® agitator will keep particles suspended in the slurry while large, 30 mm holes in the strainer have allowed virtually all of the solids to pass through.

The pumping components of the ScatPump®, notably the agitator, impeller and wear plate are constructed of high-chrome iron, meaning the ScatPump® is designed to be a solid workhorse in any condition.

The ScatPump® slurry pump is available in 4 kW to 22 kW and well suited for areas such as;

- Mill Sumps

- Fly Ash

- Residue Ponds

- Conveyor Sumps

- Wash Down Sumps

- Stockpile Runoff Sumps

The ScatPump® is also available in a smaller version for those places where a submersible slurry pump is required but the areas are too tight, introducing the “MiniScat”. This model is available in a 1.5 kW and a 2.2 kW unit. The MiniScat also comes equipped with Smarts. The Smarts include incorrect direction detection, level sensor which shuts off the pump and restarts once levels return, thermal shutdowns with a temperature adjuster to restart.

Combined with our high level of service and expertise, PumpEng® is the natural choice for all of your slurry submersible pump requirements.

Models

ScatPump®

ScatPump Mini

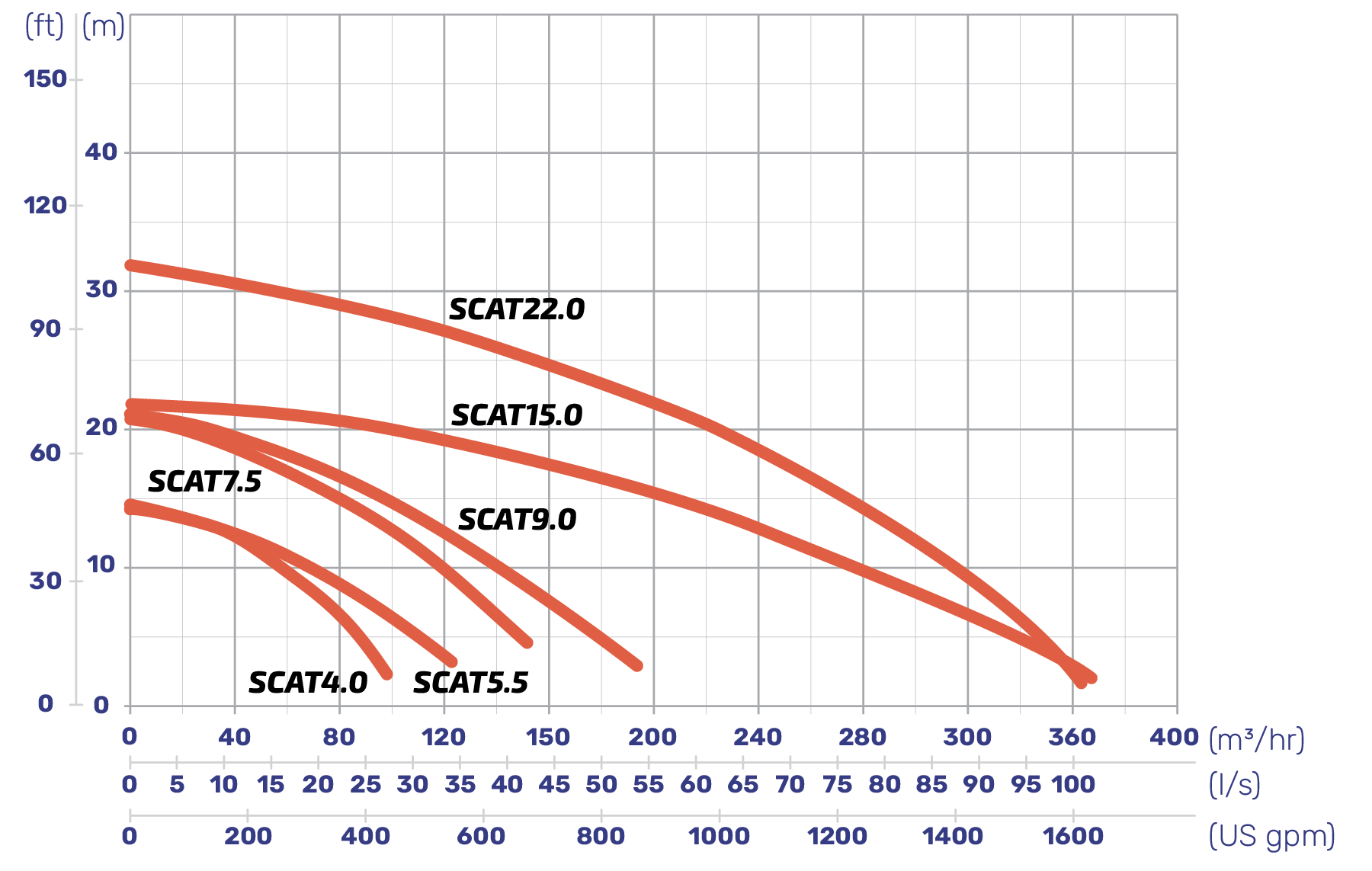

ScatPump® Power Curves (50 Hz 1450 rpm)

PumpEng®through consultation with the Australian Mining Industry, introduces its new range of Submersible Slurry Pumps, the “ScatPump®”.

Applications:

- Mill scat sumps

- Harbour construction

- Ash transfer

- Silt removal

- Sand and gravel pumping

- Barge and tank cleanout

- Lime slurry

- Coal runoff sumps

- Food waste

- General slurry duties

The ScatPump® has been designed to efficiently pump contaminated fluids containing solids in suspension to a maximum of 70% by weight.

A heavy-duty HICR agitator helps keeps solids in suspension.

The ScatPump® series are small, slimline and lighter than a Vertical Cantilever Sump Pump, thereby offering cost reductions & savings in man-hours, repairs and transportation.

Why The ScatPump® Pump Range Is Better

ScatPump® Model Overview

| Model | kW | Discharge | Phase | Solids Passage in mm | Max Head in m | Max Flow m3/min | Max Diameter mm | Height mm | Weight kg |

|---|---|---|---|---|---|---|---|---|---|

| Scat 4.0 | 4.0 | 3" | 3Ø | 30 | 15 | 1.6 | 350 | 730 | 119 |

| Scat 5.5 | 5.5 | 4" | 3Ø | 30 | 16 | 2.3 | 415 | 730 | 145 |

| Scat 7.5 | 7.5 | 4" | 3Ø | 30 | 22 | 2.7 | 434 | 776 | 170 |

| Scat 9.0 | 9.0 | 6" | 3Ø | 30 | 22 | 3.0 | 434 | 776 | 183 |

| Scat 15.0 | 15.0 | 8" | 3Ø | 30 | 22 | 6.2 | 484 | 980 | 278 |

| Scat 22.0 | 22.0 | 8" | 3Ø | 30 | 32 | 6.0 | 578 | 1200 | 434 |

ScatPump® Motor Specifications

| Type | Submersible Continuous Duty |

| Pole | 4-Pole |

| Insulation Class | F Class |

| Motor Power Details | 415 V, 3 phase, 50 cycle |

| Protector | Auto-cut (over-heat & over-load) |

| Max Liquid Temp | Fluid at 40° C |

| Protection Class | IP-68 |

| Max Submergence | 15 m |

| Materials | Jacket: Ductile iron 35-40 HRC Shaft: 420 stainless steel Cable: 10 m Standard Seal: Sic-Sic/Sic-Sic |

ScatPump® Pump Specifications

| Impeller | High Chrome Semi-open Impeller |

| Wear Plate | High Chrome |

| Mechanical Seal | Sic-Sic/Sic-Sic |

| Bearing | Heavy duty bearings grease lubricated |

| Agitator | Replaceable, High Chrome |

| Volute Casing | Hardened Ductile Iron |

ScatPump® Unique Design Features

Submersible cable with epoxy fill to raise moisture resistance. Sizes, styles and length are available to meet your specific requirements.

Double silicon carbide mechanical seals in an oil bath offering abrasion resistance and snore running capability. Wear Protection ring is also fitted.

Windings are class F/H and incorporate an overheat and overload protection.

Top discharge, self venting design means no more airlocks. Jacketed design ensures motor is always cooled even when pumping within inches of the bottom.

Semi Open, HICR hardened impeller resists abrasion and allows the pumping of large diameter solids.

The HICR agitator helps to keep solids in suspension thereby minimising the issue where the water is pumped but the solids are left in the sump.

A HICR wear plate to reduce abrasion. Can be adjusted externally to keep efficiency at a maximum.

Replaceable stainless steel shaft sleeve to protect the shaft.

ScatPump® submersible pumps are smaller, lighter, easier to repair and offer substantial operational savings when compared to cantilever sump pumps

Product Range:

Guardian® | JetGuard® | Raptor® | ScatPump® | MetalVest™

By Application:

Mining Pumps |

BIBO Compatible Pumps | Dirty Water Pumps | Slurry Pumps | High Head Pumps

Quick Links:

Pumps | Pump Shop | Pump Parts | Pump Service | Pump Hire | Contact