About Us

PumpEng is on a mission to redefine underground mine dewatering, prioritising excellence at every turn. Our commitment to innovation, reliability, availability, and personalised support throughout the product lifecycle ensures every mine operator a good day at work.

PumpEng is an Australian-based global Original Equipment Manufacturer (OEM) with a rich history of supplying submersible pumps to the mining sector.

Tailored Solutions for Mining

Recognising the unique requirements of miners worldwide, we specialise in designing innovative submersible pumps for the most difficult environments. Our collaborative approach involves working closely with clients across continents to design dewatering equipment solutions to withstand the pressures of diverse operational environments.

Comprehensive Global Product Range

Our diverse product portfolio covers mining, construction and mineral processing applications. PumpEng offers a comprehensive suite of dewatering pumps designed to handle requirements in various challenging environments.

Empowering Application Awareness

Our pumps incorporate the latest advancements, contributing to energy efficiency, reduced maintenance costs, and overall operational excellence for clients worldwide. To reap these benefits, we work with our partners to create a system that supports using the right pump for the job. We also empower on-site service teams with an easy-to-follow pump identification system and simple online access to key installation information.

Your Trusted OEM Partner

At the heart of PumpEng lies our expertise in global OEM manufacturing. We are a strategic partner with a worldwide reach. Our extensive manufacturing capabilities ensure clients receive high-quality, tailored pumping equipment wherever they operate.

Client-Centric Approach

At PumpEng, our global reach matches our commitment to building enduring partnerships with clients worldwide. Our client-centric approach involves active collaboration, ongoing support, and exceptional customer service regardless of geographical location. We value feedback and continually strive to exceed expectations, ensuring the success of our clients' operations globally.

Conclusion

PumpEng stands tall as a beacon of global OEM manufacturing excellence, embodying reliability, innovation, and customer-centricity in the pump manufacturing industry. With a legacy built on trust and performance worldwide, we remain dedicated to pushing the boundaries of what is possible in fluid handling solutions.

Delivering Global Quality Standard

Quality Assurance on a Global Scale: Our commitment to quality knows no borders. Rigorous quality control measures, from design to production, support our pumps' durability, reliability, and longevity. We adhere to international industry standards, ensuring our products meet or exceed clients' expectations. We have assembled a highly skilled technical team to support delivering this quality work.

Global Environmental Responsibility

We recognise the importance of sustainability on a global level. PumpEng is committed to developing eco-friendly pump solutions that minimise energy consumption and environmental impact. Our efforts align with our dedication to responsible manufacturing practices.

Picture this. You're in Australia’s iconic mining town - Kalgoorlie, so often the heart of innovation in mining practices that make their way around the world. Mine dewatering specialist Paul Meneghel is in his element, studying the points of failure in mining pumps from the market leaders of that time. He is mentally taking them apart and imagining a better way to build them.

He shares his ideas but quickly decides if you want something done, it is best to do it yourself. His fledgling company first designs and builds tougher parts. Then it designs and builds tougher pumps. PumpEng innovates with a whole new approach to managing dewatering systems for mines. The innovative pumps and methodologies developed by PumpEng are now an industry game changer. There's a whole world of underground mining operators interested in transforming their dewatering systems. They are signing up to Do It Different and Do It Right.

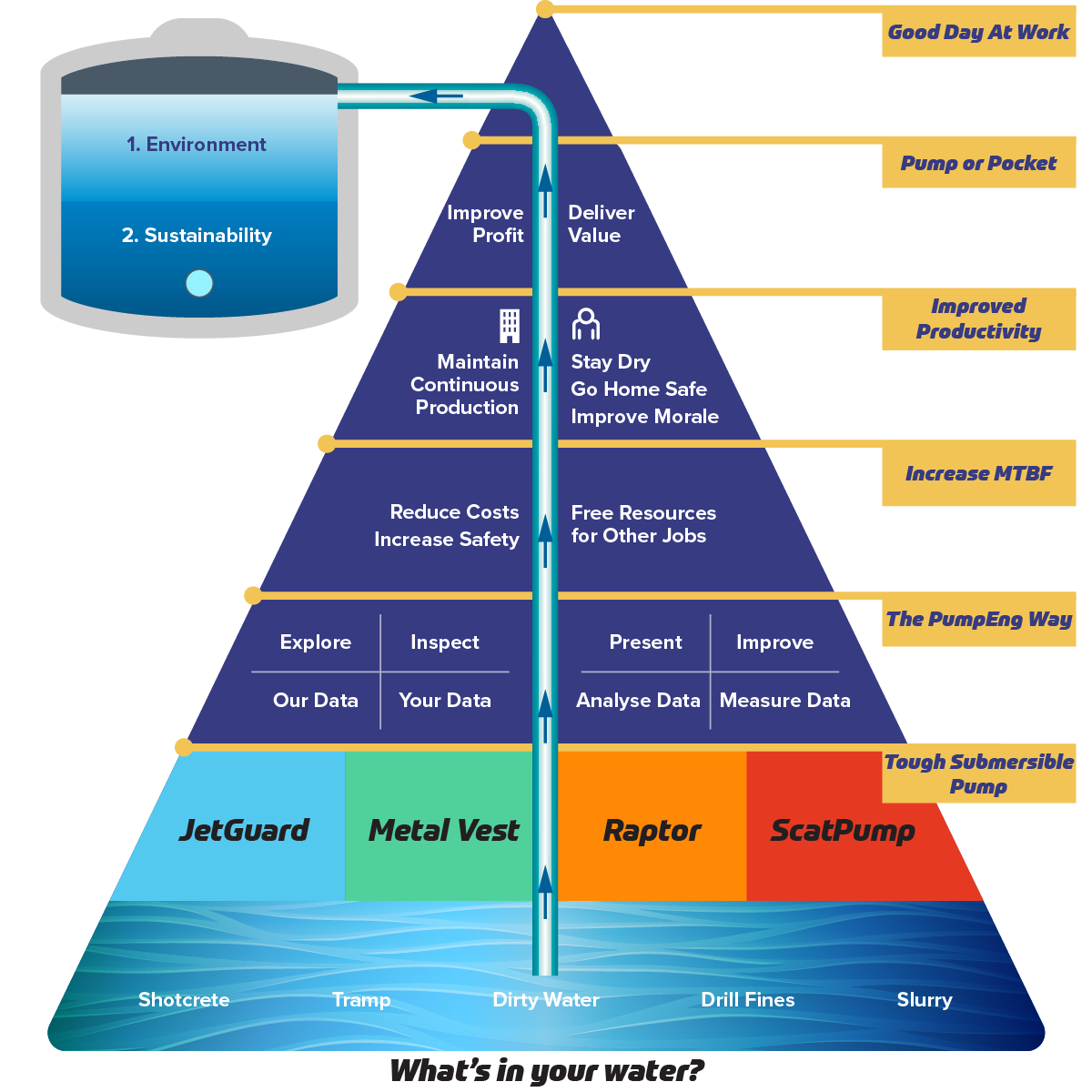

PumpEng makes pumps with a focus on delivering A Good Day at Work for the underground mining operators and their crews. While dewatering pumps may seem a small part of a mining operation, pump failure can have multiple knock-on effects that can cause production delay, cost blowouts and increase hazards in the workplace. In short, if you can improve your dewatering system, you can have a big impact on productivity, morale and safety.

PumpEng transforms the efficiency of mine-site dewatering because it goes further than just supplying pumps. The PumpEng Way is a partnership based on data-driven continuous improvement. It ensures that the crews on site consistently use The Right Pump For The Job.

So let's take a closer look at each part of what makes PumpEng a very different pump manufacturer and dewatering partner.

Less Production Delays

Production delay on a mining site is stressful and expensive for everyone, from the maintenance crews to production schedules managers and those responsible for cost overruns. No one is happy about delayed production schedules and crews constantly in the water swapping over old fashioned pumps that can't cope with the conditions.

Longer Pump Life

PumpEng design and manufacture pumps and parts specifically built to handle the tough conditions of the modern mine where Shotcrete fibre is present in the wastewater. These tougher pumps have several inbuilt defences that have dramatically increased pump life.

Free Up Maintenance Crews

Perhaps the happiest people of all are the maintenance crews who spend far less time in the water and are free to get on with important preventative maintenance work on the mine site. Mine managers get fewer complaints from everyone right through the operation. The phones stop ringing because things now operate differently - different pumps and a different problem-solving partnership in place.

Explore Your Options - Obligation Free

The PumpEng Way is a very different approach to dewatering. PumpEng doesn’t just sell a pump and walk away, instead, they regard every customer as a partner. There is a company-wide commitment to constant improvement and problem-solving. If you'd like to explore your options and learn about The PumpEng Way, we'd be very happy to talk with you, obligation free. We can explain some elements of our approach right here.

Site Inspection - Build Insight into Your Needs For Current and Future Developments

Every underground mine is going to have a number of dewatering sites. These will differ in the type of challenges, such as water quality, slope and water volume. Experienced PumpEng engineers will inspect the mine to learn about each of these sites. They will listen to the people on the ground to better understand what is affecting the smooth running of that part of the dewatering operation.

Present Solutions - Devise Data-driven Solutions for Reliable Dewatering Pumps

Once PumpEng has identified which dewatering strategy is most suitable in each circumstance, that system will be implemented. Any pumps returned will be studied to determine the point of failure and adjust the approach for that site accordingly. This might be the selection of a different pump or an adjustment to pump operation.

Continuous Improvement - Quarterly Data Analysis & System Improvement - A Partnership

PumpEng is committed to working closely with you to constantly improve how your dewatering system operates. They will follow up with quarterly reviews of the site to evaluate and improve the performance of that dewatering system.

Unique Identification System - Making It Easy for Crews to Make The Right Choice

Many mining sites have crews who are constantly changing and unfamiliar with the dewatering equipment. PumpEng has created a unique identification system to make it easy for maintenance crews and supply managers to ensure the right pump is used for the job.

Data and Feedback - Adjusting Pumps to Match Conditions

If dewatering conditions change within the mine, pump performance data alerts PumpEng to the changing conditions and how the dewatering system will be adjusted to accommodate that change.

Innovative Pump Design Rewriting Industry Performance Standards

The innovative design of PumpEng dewatering pumps and parts has rewritten the industry standards for pump life. While the operating conditions differ from mine to mine, operators are seeing at least a doubling of mean time between failure. Many are seeing even better than that. They are also reporting reduced costs of servicing because the pumps are less damaged.